Crushing hammer is a common excavator attachments, in order to function for a long time and become a gold-digging tool, it is necessary to use it reasonably and maintain it correctly like other tools. Here, we have compiled some common phenomena of the crushing hammer, users need to pay attention to in the daily use.

1.Signal of insufficient grease

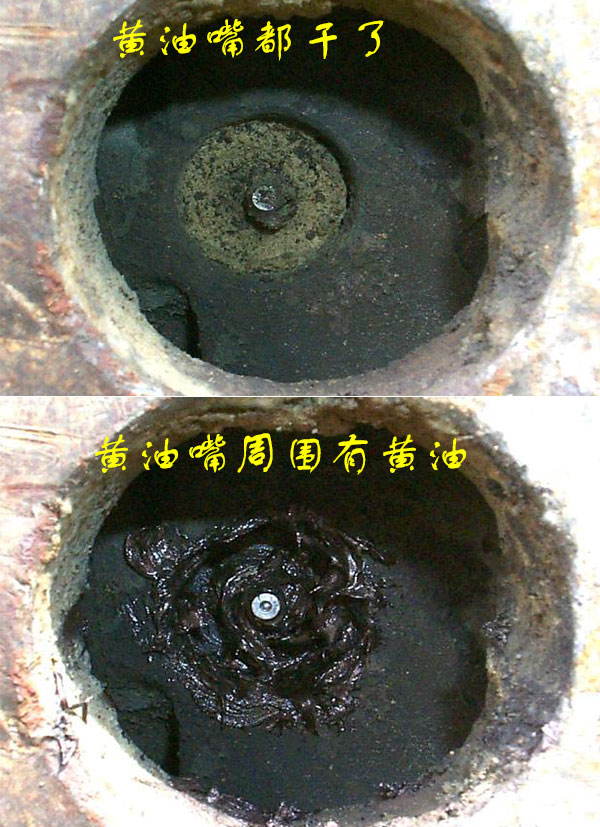

Crushing hammer work needs grease for lubrication, if the grease is insufficient, it will speed up the wear and affect the life. Correct use of grease can be observed on the brazing rod a small amount of oil stains, insufficient grease will appear dry, and if the use of incorrect grease such as low melting point, or contaminated grease, then the grease will flow down the brazing rod.

In addition, you also need to observe the grease nipple on the crushing hammer, if the grease is dry around the nipple, then the crushing hammer will certainly not be well lubricated, which may also be one of the reasons for the failure of the crushing hammer.

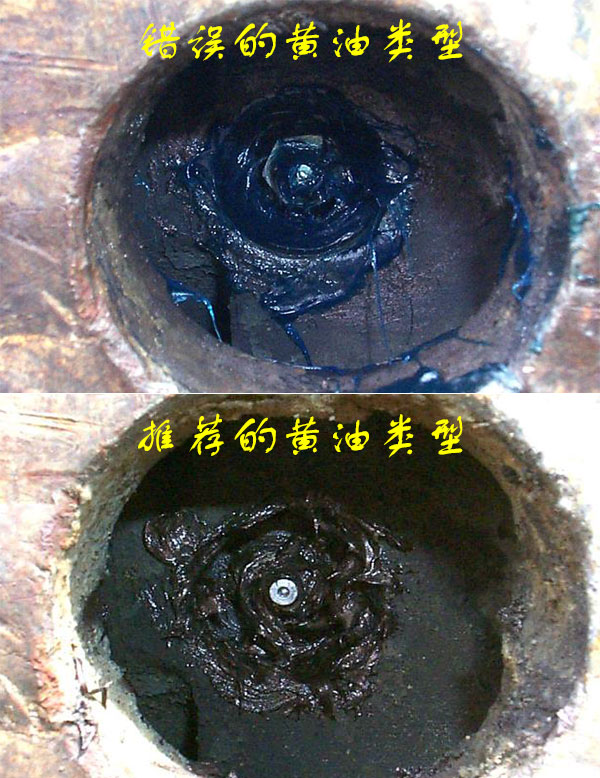

2.Wrong type of grease

Try to use the type of grease recommended by the manufacturer for the melting point.

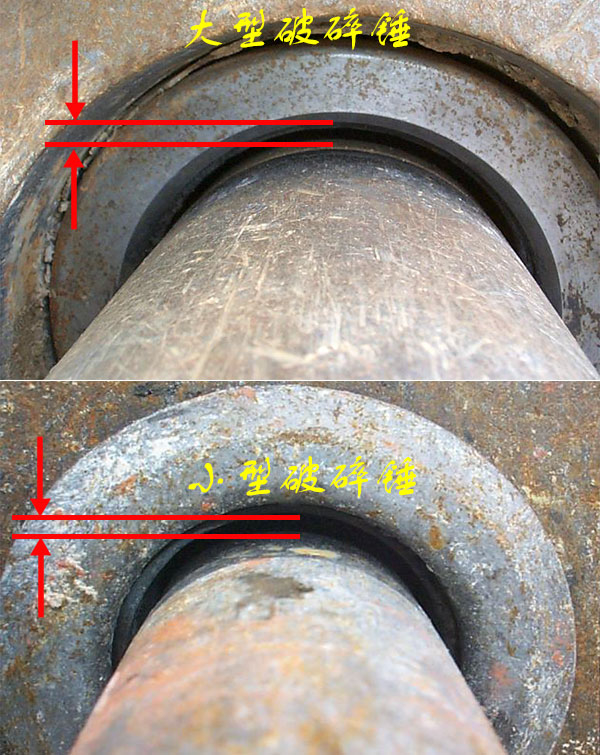

3.Wear and tear over the limit

After a long period of use, some crushing hammers will experience wear beyond the permissible limits, which is largely due to insufficient grease supply. In checking this you can wiggle and rotate the brazing rod in different directions, if the gap is more than 5mm in any direction then it should be over the limit and needs to be dismantled for further inspection.

Remove the guard plate of the crushing hammer, check whether the lubrication line is blocked, and measure the wear and tear.

4.Beware of counterfeit parts

The use of the correct parts is an important factor in the proper functioning of the hammer, and counterfeit parts may damage the hammer. There is no way to go into detail about this, it is up to the user.

5.Wrong storage method

When the hammer is not in use, it needs to be stored correctly, and the hydraulic lines must be closed. Dust, dirt, water, etc. entering the hydraulic system can result in considerable repair costs.

6.Pay attention to missing parts

Keeping the crushing hammer in good condition is very important for normal use, and you cannot operate a crushing hammer with missing parts. Therefore it is important to spot missing parts and replace them in a timely manner.

7.Avoid damaging the housing

Do not use the mounting ring for anything other than lifting, as this may damage the ring and the housing. For normal use, remove the ring and replace it with a bolt to avoid dust.

8.Check the wear of the retaining pin

If it is worn, it can be turned 180 degrees or replaced. If it is worn on both sides, it can only be replaced.